Exporters of multilayer blown film lines

Download Catalogue

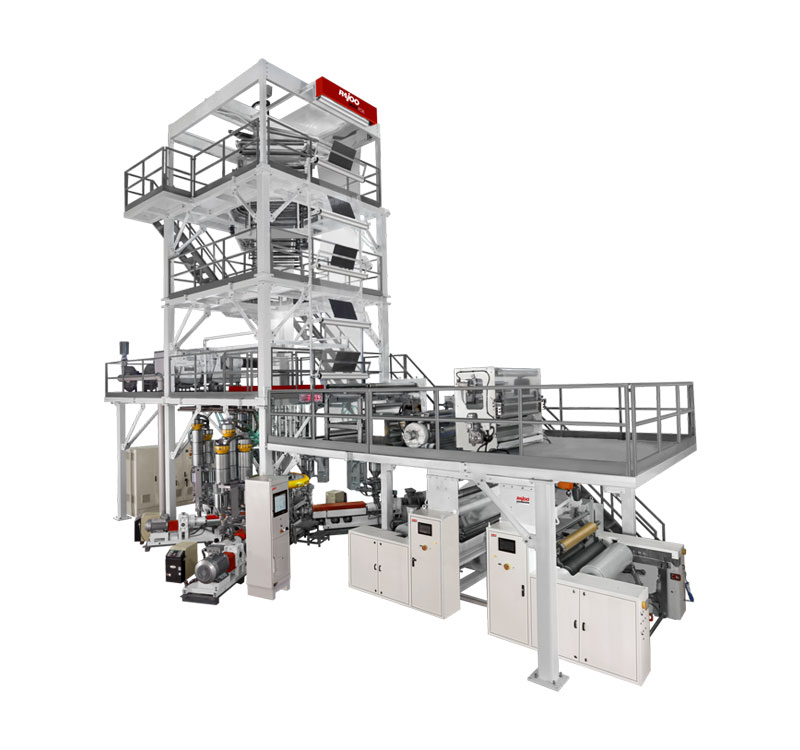

MultiFoil ®

Three Layer Blown Film Lines

Multifoil co-ex blown film lines are backed by proven engineering experience of Rajoo for over three decades and are available in three layer configuration for general purpose packaging films and cross-laminated films with output ranging from 120kg/hr to 1500 kg/hr and lay-flat width ranging from 600mm to 5000mm.

Multifoil – 3 layer blown film extruders are offered with direct coupled motors, fluid temperature controllers for grooved feed section along with manual or hydraulic screen changer.

Multifoil – 3 layer blown film line with CSD- Cylindrical Spiral Die (bottom fed vertical cylindrical spiral system) is state-of-the-art and provides optimized layout for rheological and thermodynamic criteria. Number of overlaps are almost unlimited, thus imparts excellent thickness distribution with broad range of operating parameters. Melt streams are designed and merged according to specific flow behaviour of polymers. It is compact in design with low axial forces. Sizes of all flow channels, all spiral dimensions and coex flow region are determined with the aid of computerized design and 3D simulation software. The die is self-cleaning. It is highly polished eliminating dead spots. Surfaces in contact with the melt are especially hard chrome plated and polished to ensure rapid flushing resulting in low wastage and short non-productive times during resin change. Short polymer flow passages decrease residence time which is of great benefit when processing thermally sensitive materials and reduces polymer degradation.

Multifoil – 3 layer blown film lines are available with advanced automation features like integrated material conveying, gsm control, gravimetric blending and dosing, non-contact type IBC system with digital correction, automatic thickness control, fully automatic center-gap-surface winder and integrated process control. A range of system solutions can be configured to adapt to the ultimate processing needs.

Applications

Lamination grade film, Liquid packaging film, High dart FFS resin sack film, Cereal packaging film, Short shelf-life oil packaging film, Pharma and medical grade film, Pallet hooding shrink/stretch film, Greenhouse film, Silage and mulch film, Geomembrane film, Pond, canal and container liners and Soap packaging films