Suppliers of pvc extruder

Download Catalogue

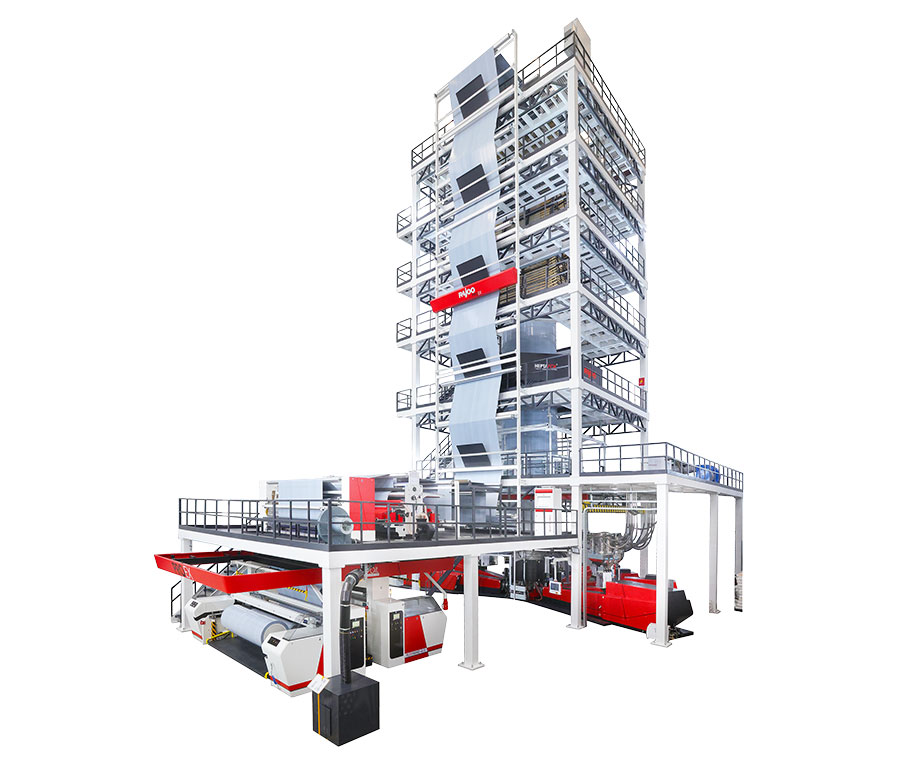

PROEX ®

PROEX

At Rajoo Engineers, we are dedicated to shaping the future of plastics extrusion with innovation and excellence. The PROEX Series is the embodiment of our commitment to delivering high-performance machinery tailored to meet the evolving needs of modern production environments. Designed with a strong focus on efficiency, precision, and sustainability, the PROEX Series is here to elevate your blown film production to new heights.

Are you looking for a co-extrusion blown film line that combines high output, superior film quality, and energy efficiency?

Discover the PROEX Series

A high performance blown film extrusion line from Rajoo Engineers, crafted for converters who demand precision, maximum productivity, and a sustainable approach to flexible packaging

Key Features of PROEX Series:

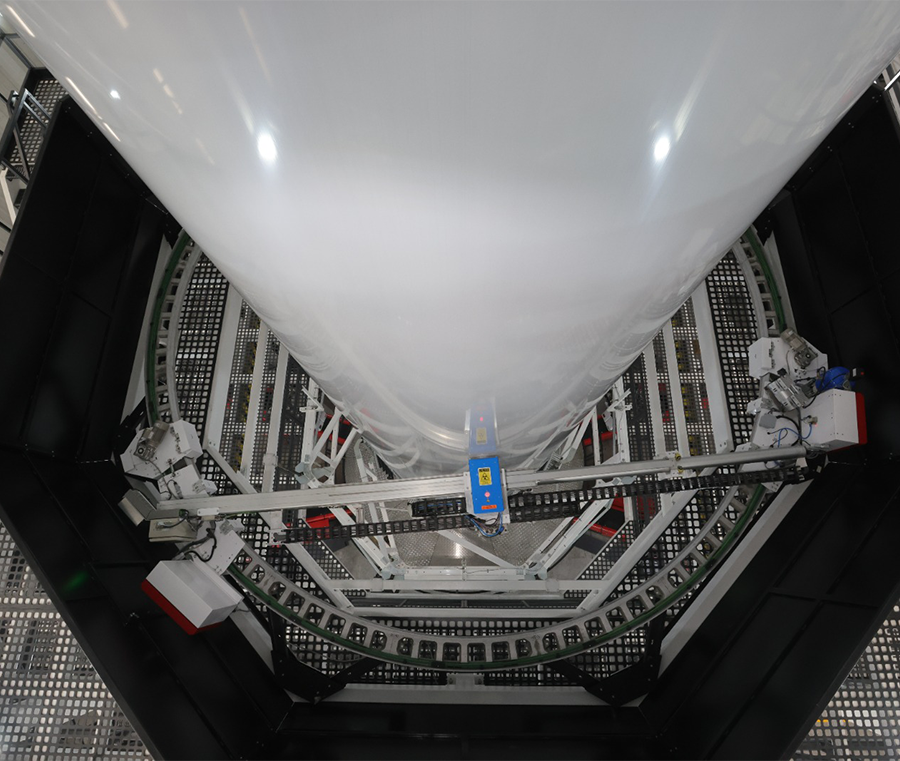

- Intelligent Control Systems: Incorporating advance automation, the PROEX Series offers real-time monitoring and precise adjustments, empowering you to optimize your operations, maintain film quality and maximize productivity.

- Energy-Efficient Design: Our focus on energy efficiency helps lower operational costs, making the PROEX Series an environmentally responsible and cost-efficient choice for your business.

- Versatility Across Applications: No matter the complexity of your materials or blown film production requirements, the PROEX Series is designed to produce a wide range of applications, giving you the flexibility to diversify customize your product offerings.

- Built to Last: With top-tier materials and meticulous engineering, the PROEX machines are designed for durability, ensuring reliability and long-lasting performance in your production line

Real Time monitoring

Recipe Storage

Prevent & Predict

Production Issue

Safety Alarms

Remote Diagnostics

Transform Your Production with PROEX

The PROEX Series is more than just a blown film line; it's a strategic option in achieving operational excellence. Whether you're looking to boost productivity, improve product quality, or reduce energy costs, PROEX is engineered to deliver tangible benefits for your business.

Step into the future of extrusion. Reach out to Rajoo Engineers and discover how the PROEX Series can optimize your production and help your business thrive in a competitive marketplace