Exporters of multilayer blown film lines

Download Catalogue

MultiFoil - X TM

Cross Lamination Film Line

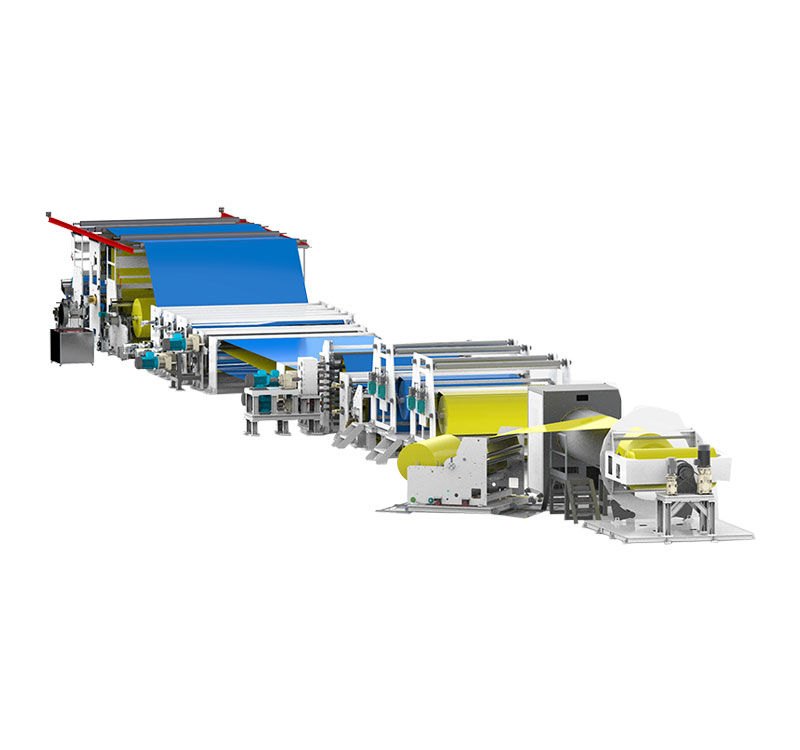

Rajoo offers Multifoil – X, a combo product of 3 layer blown film line along with spiral cutting system with winder and stretching & laminating line backed by proven engineering experience of Rajoo for over three decades for Cross Laminated film aimed at helping with specific yet customized insights that are relevant to market specific challenges.

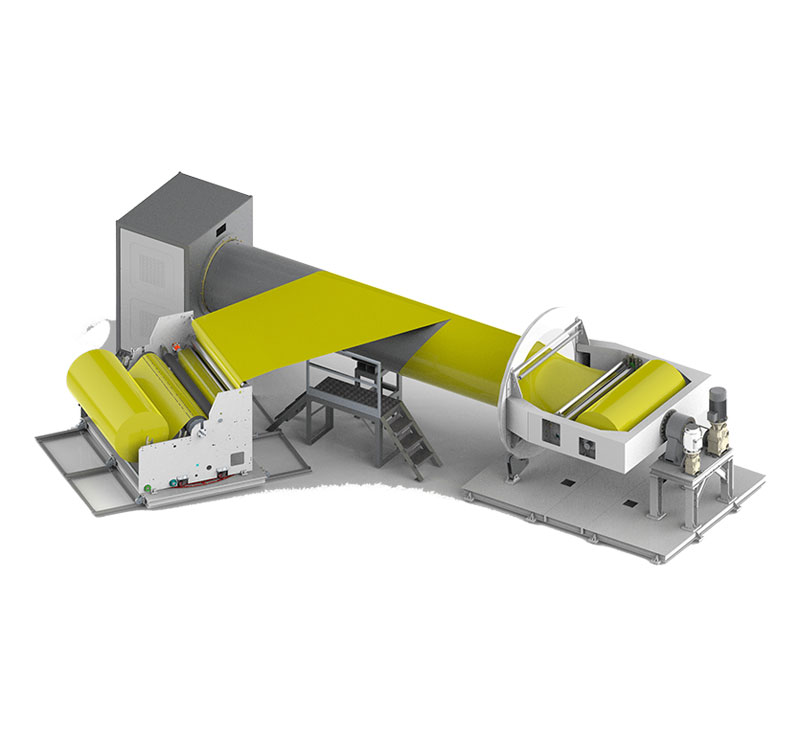

Multifoil X – 3 layer blown film extruders are offered with direct coupled motors, fluid temperature controllers for grooved feed section along with manual or hydraulic screen changer, CSD- Cylindrical Spiral Die (bottom fed vertical cylindrical spiral system), calibration basket, oscillating haul off and surface winder.

The process is to produce PE cross laminated tarpaulin by extruding molten resin into a continuous film. In this process resin and required additives are fed into extruders through a hopper. Heat and friction in the barrel convert the resin and additives to a melt and mixed homogeneously, which is forced through a cylindrical spiral die to form a film.

The screw pushes the polymer from the hopper to the die end; compressing, melting and increasing the pressure on it as it pushes uniformly in the die.

A filter screen is placed between the end of the extruders to catch contaminates , un-molten polymer and some gel particles. The generic screen is a plate with regularly spaced holes. The screen pack is then placed against a breaker plate.

The tubular film coming out from the die is cooled. For cooling the film, cooling air is continuously flowing around and inside the tubular bubble and at the same time removing the hot air from inside the bubble.

Then the film is pulled by take-off rolls and guided to the winder through guide rolls. The film is wound on the winding shaft.

Cross cutting process basics:

Wound film rolls are then mounted on an unwinding station of cross cutting unit. The tube is pulled through highly polished and galvanized pipe of suitable diameter with sufficient air-flow where tubular film is cut into lay-flat film with a suitable degree of cross cutting. Cut film wound on winder is arranged at 45 degree near cross cutting unit.

This roll is then mounted onto an unwinding station which is then fed into a pre-heating unit to stretching unit to four station winders to wound finished product.

Applications

Agriculture & Horticulture

Spice drying, Grains drying, Cotton covers, Vermi beds, Poultry curtain and Fumigation of grain

Marine

Boart covers, Tortoise breeding, Fish boat roots and Fish breeding

Construction

Construction building covers, Construction flooring and Pond liner

Mining

Covers the mine ore

Transportation

Machinery packaging during transportation, Truck covers and Railway root covers

Automobile covers

Car covers and Two wheeler covers