Five layer blown film lines

Download Catalogue

PentaFoil ®

5 Layer Blown Film Lines - 5 Layer POD

5 Layer co-ex blown film lines are tailored to meet specific needs, for both barrier and non-barrier POD films for various application segments such as collation shrink films, lamination grade films, milk and water pouches, edible oils and more with outputs ranging from 250 kg/hr to 1500 kg/hr and lay-flat width ranging from 1200mm to 5000mm.

Pentafoil – 5 layer blown film lines are offered with direct coupled motors, fluid temperature controllers for grooved feed section along with manual or hydraulic screen changer.

Pentafoil – 5 layer blown film line with CSD- Cylindrical Spiral Die (bottom fed vertical cylindrical spiral system) is state-of-the-art and provides optimized layout for rheological and thermodynamic criteria. Number of overlaps are almost unlimited, thus imparts excellent thickness distribution with broad range of operating parameters. Melt streams are designed and merged according to specific flow behaviour of polymers. It is compact in design with low axial forces. Sizes of all flow channels, all spiral dimensions and coex flow region are determined with the aid of computerized design and 3D simulation software. The die is self-cleaning. It is highly polished eliminating dead spots. Surfaces in contact with the melt are especially hard chrome plated and polished to ensure rapid flushing resulting in low wastage and short non-productive times during resin change. Short polymer flow passages decrease residence time which is of great benefit when processing thermally sensitive materials and reduces polymer degradation.

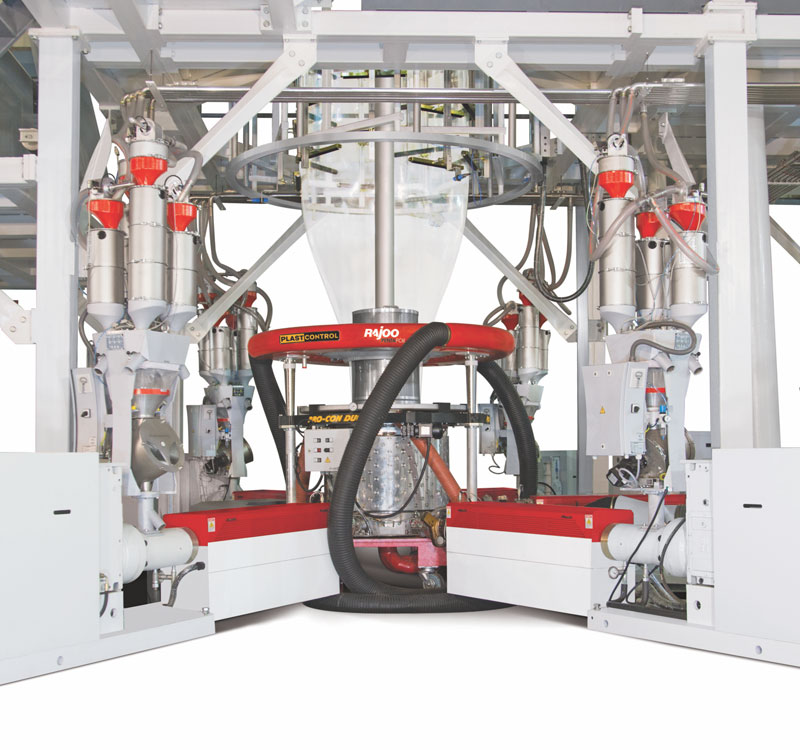

Pentafoil – 5 layer blown film lines are customized based on films to be produced, as such, there are no generic machine configurations. 5 layer blown film lines are available with advanced automation features like integrated material conveying, gsm control, gravimetric blending and dosing, non-contact type IBC system with digital correction, automatic thickness control (with non-contact capacitive sensor or gama backscatter nuclear sensor) and fully automatic center-gap-surface. Integrated touch screen based supervisory process control is provided thus rendering it operator friendly.

Applications

High dart FFS resin sack film, Cereal packaging, Courier bags / security bags, Surface protection film, Stretch hood hold film, Compression packaging film, Shrink film, Lamination grade film and Meat & cheese barrier packaging film