Exporters of multilayer blown film lines

Download Catalogue

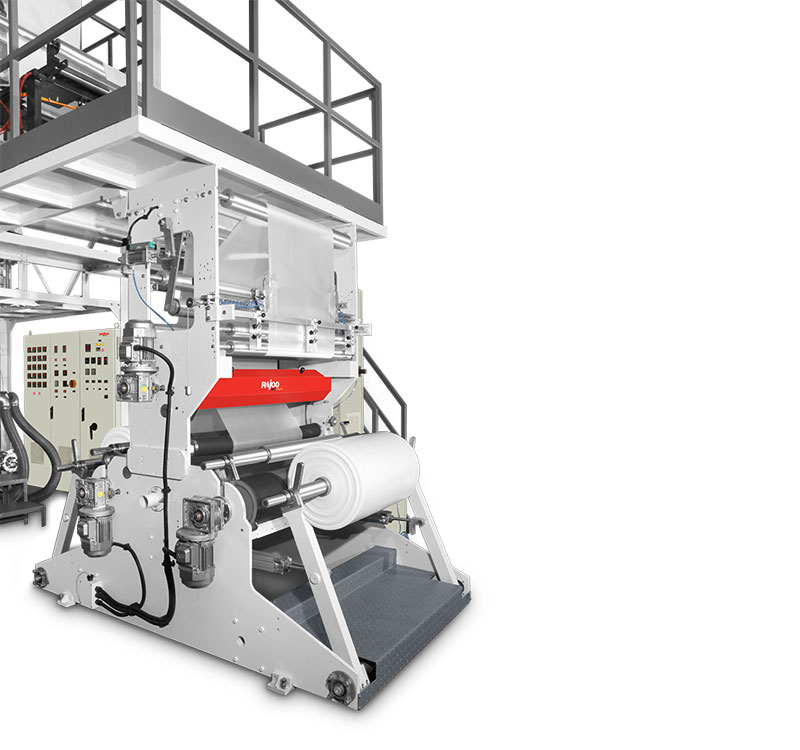

MultiFoil - LITE TM

Two extruder 3 layer ABA blown film line

The MULTIFOIL - LITE comes with the trademark quality of Rajoo machines coupled with a minimal cost of ownership, minimal downtime, energy efficient, flexibility to adapt to varied applications to ensure a sustained competitive advantage for its customers.

The MULTIFoil LITE a 2-extruder / 3 layer (A-B-A, A-A-B or A-B-B type) blown film line, empowers its customers to remain aggressive in the highly competitive bag making industry, plagued with increasing costs of raw materials. With MULTIFoil LITE, it now becomes very convenient to use even up to 50% calcium carbonate or recycled material (in the core layer) with virgin material in the skin layers. The abrasive materials would normally impact machine parts adversely but proven Rajoo quality ensures minimal wear and tear even when high percentage of filler material is used, as the screw and barrel are especially designed and coated.

The Multifoil Lite –2 extruders 3 layer blown film line are offered with direct coupled motors, grooved feed section, manual screen changer, CSD- Cylindrical Spiral Die & airing, oscillating haul-off for gauge randomisation and dual station winder suitable for various applications.

Rajoo’s MULTIFoil LITE is designed to run with A-B-A configuration, it’s specially designed cross head provides the flexibility to run A-B-B and A-A-B configurations as well, another first for the industry from Rajoo.

The Multifoil Lite –2 extruders 3 layer blown film lines are available with advanced automation features like integrated material conveying, gsm control, gravimetric blending and dosing fully automatic surface winder and integrated process control.

Applications

Shopping and courier bags, Milk & water pouches film, Tarpaulin film, Lamination grade film (with slip on one side and non-slip on the other), Mulch film and Shrink film